In this blog post, our Machine analyst uncovers the role of ceramics in Electric Vehicle (EV) production & innovation.

The EV Revolution

There is a growing demand for EVs, and the push by governments towards electrification, with the electric vehicle market projected to reach $823.75 billion by 2030. According to the International Energy Agency, EVs will represent 60% of the vehicles sold globally by 2030. In 2022 Tesla became the world’s most valuable automaker selling over 771,300 Tesla Model Y and capturing 50% of the US market share. Other automotive giants are being forced to react – Ford planned to invest $50 billion in electric vehicle and battery production to keep pace by 2026.

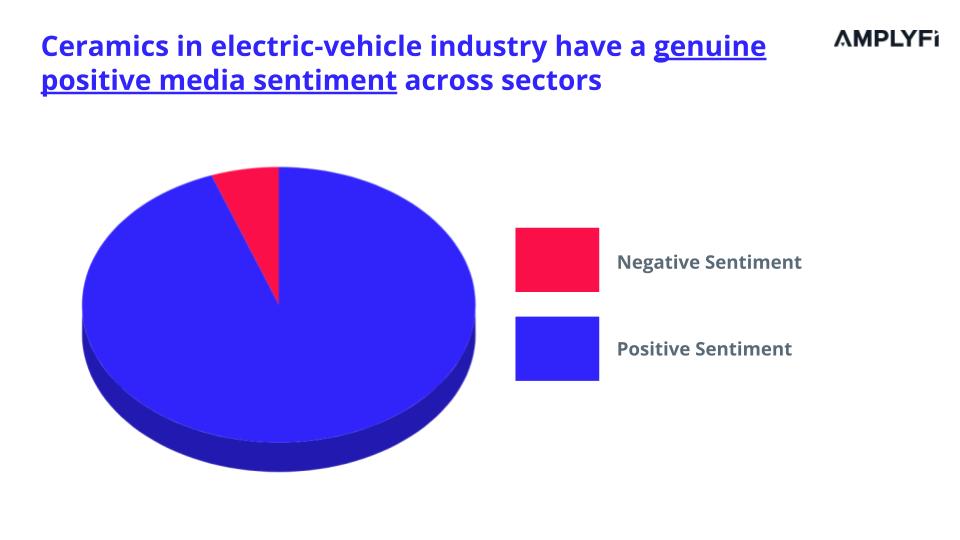

Ceramics are crucial in electric vehicle technology due to their excellent thermal and electrical properties. The automotive ceramics market was worth $1.47 billion in 2019, but it is expected to reach $2.11 billion by 2027. AMPLYFI’s AI-powered analysis of media trends and discussions about electric vehicles and ceramics shows an incredibly positive sentiment and a strong connection strength.

Role of Ceramics - Batteries, Motors and Others

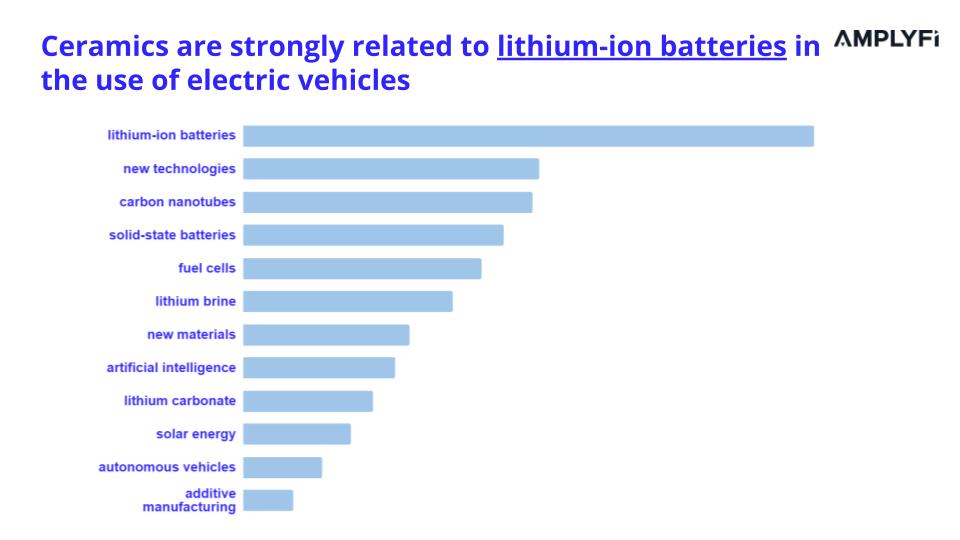

Ceramics and lithium-ion batteries are widely discussed in online media. In the above figure, our analysis reveals their connect strength, followed by energy-related phrases, including autonomous vehicles. Scientists at Vienna University of Technology developed a ceramics battery offering an extremely long lifespan and doesn’t require rare earth metals – an ideal solution for large storage systems therefore, it could replace the traditional lithium-ion batteries

Batteries

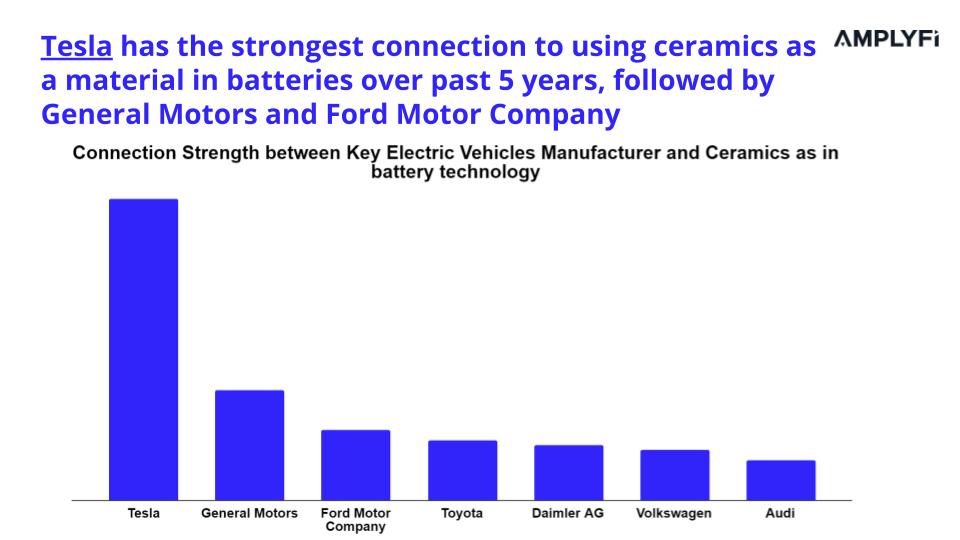

Tesla is at the forefront of using ceramics in EV batteries, taking the lead in enhancing performance with improvements in energy density, thermal stability, and safety. Using ceramic filters in the battery electrolyte to enhance ionic conductivity can result in faster charging and longer-lasting batteries.

Motors

Ceramic materials are used in motor components, including bearings, rotors, and stators, to improve their performance and efficiency. Some widely used materials include silicon nitride and aluminium oxide, which are preferred for their thermal and mechanical properties.

Other Components

They are widely used in other EV components for example, ceramic coatings and thermal management are crucial in maintaining the optimal temperature of electric vehicles’ battery packs, electric motors, and other electronic components. Manufacturers prefer these coatings because they can improve thermal insulation efficiency and prevent the overheating of critical components.

The figure below indicates that Tesla leads the use of ceramics in EV batteries, followed by General Motors and Ford. AMPLYFI’s ML model shows their connection strength.

Future Developments for Ceramics in EVs

Research and development in ceramic materials are critical for advancing electric vehicle technology. Scientists and engineers are exploring new materials and processing techniques to enhance the properties of ceramics, such as developing more efficient and cost-effective manufacturing processes and improving the durability and reliability of ceramic components.

Some technologies worth paying attention to for anyone with a strategic interest in the space:

- Solid-State Batteries: A solid-state battery is an advanced battery technology that uses a solid ceramic electrolyte instead of a liquid electrolyte, offering higher energy density, faster charging, and increased safety compared to traditional lithium-ion batteries. These batteries could offer ranges of up to 1,000 kilometres on a single charge. According to a report by IDTechEx, the solid-state battery market may reach $8 billion by 2031.

- Thermal Management: It involves cooling batteries, motors, and power electronics while regulating the temperature in the EVs. Ceramic materials with high thermal conductivity serve as insulation and heat sinks – a device to enhance heat dissipation. The global thermal management market is to surpass $19.3 Billion by 2028.

- High-Temperature Superconductors: Researchers explore high-temperature ceramic superconductors for EV motors to enhance performance, range and efficiency while reducing energy consumption. A report suggests that the high-temperature superconductor market is expected to reach $12.4 billion in 2023.

Ceramics offer great potential to enhance EVs’ efficiency, reliability, and sustainability, leading to a bright future for EVs while overcoming the challenges.

Challenges of Using Ceramics Materials in EVs

Despite the obvious benefits, no solution comes without its challenges. Overcoming these will be key to organisations seeking to leverage Ceramics in their Electric Vehicles long-term and at scale.

- Environmental Impact: One of the greatest challenges is that ceramics production requires significant energy and impacts the environment. The estimated worldwide natural gas consumption for firing ceramics is 182 TWh. Developing sustainable production methods for ceramics is crucial to minimise their environmental impact.

- Materials Shortage: Production costs for raw materials will continue to increase in the next 4 years The raw materials shortage may spike EV battery costs to 22% by 2026.“The tsunami of demand is coming,” said Sam Jaffe, vice president of battery solutions at E Source.

- Fragility: The covalent and ionic bonds in ceramics make them more brittle and prone to cracking under stress or impact, which can affect the reliability and safety of EV components.

- Manufacturing: The complex processing requirements of ceramics can also present challenges, as their manufacturing often requires specialised equipment and expertise.

Nonetheless, ongoing R&D in the ceramics can help overcome these challenges and improve the viability of using ceramics in electric vehicle components.

Key Innovators in Ceramics for EVs

In conclusion, Advances in ceramic materials and processing techniques are becoming increasingly important for the future of EVS technology. Ceramics offer several advantages over traditional materials, including higher strength and durability, better thermal stability, and improved electrical conductivity, with Tesla leading the way in both EV market share and investment. However, there are other leading players in automotive ceramics worth monitoring:

- Morgan Advanced Materials – founded in 1856 in the UK, net worth $0.98 billion

- Kyocera – a Japanese ceramics producer with a net worth of $17.97 billion

- CeramTec – a German company, net worth €3.8 billion, founded in 1996

- IBIDEN CO., Ltd – founded in 1912 in Japan. It is a global company with a network of operations in Asia, Europe, and the Americas.

- Corning Inc – an American materials science company with a net worth of $26.76 billion, produces ceramic materials for various industries, including EVs.

- Ceradyne Inc – a California-based manufacturer of advanced technical ceramics, was founded in 1967 and has since become a subsidiary of 3M, worth $46.46 billion.

- Saint Gobain Ceramic Materials – a French global leader in advanced ceramic materials, offering high-performance ceramics solutions, operating in 50 countries and employing 10,000 people.

Continual developments are likely to emerge swiftly as ongoing R&D budgets are deployed and consumption of EVs rise, driven by perpetual regulatory shift and the need to divest from fossil fuels